What is Textile Screen Printing? The History, Process, and More.

Ordering a custom piece of clothing? If you’re turning a plain textile into something more, you have a variety of printing methods to choose from. If you’re printing multiple copies of the same design, screen printing is the method for you. This traditional printing method is easy to understand and common in all industries.

What is Screen Printing and How Does it Work?

Screen printing is the process of transferring ink through a stencil screen onto a flat substrate. This process is also known as silk screening, silkscreen printing, pad printing, serigraphy, or serigraph printing.

Screen printing presses speed up and simplify the process. A larger screen printing press can hold and place the screen, pour the screen printing ink, squeegee ink onto the textile, and move the textile to the next screen. Smaller presses, for personal use or smaller shops, still simplify the screen printing process but require more manual control.

What can be screen printed on?

Screen printing can transfer designs from the stencil to a variety of items. The most popular textile printed on by screen printers is t-shirts. Here at Casa del Mar, we can screen print t-shirts, hoodies, foam hats, baby onesies, mugs, promotional products, and much more. It is also possible to print on canvases, posters, artwork, fabrics, textiles, decals, balloons, paper, metal, plastic, glass, and wood.

The Process of Screen Printing

1. Design Creation

a. First, the art design, logo, or graphics are finalized.

2. Screen Preparation

a. A screen with the proper mesh count is chosen. Mesh count determines how many fibers there are in one square inch. If designs are full of fine details, printers choose screens with a higher screen mesh count. Then, the emulsion type is chosen and applied to the screen. If designs are multi-colored, one screen is prepared for each color being applied.

3. Emulsion Exposure

a. To create a stencil out of the screen, a transparent acetate sheet is printed with the chosen design on them. This sheet is laid on top of the screen and then exposed to bright light. Since the sheet is transparent in all areas except the design, the areas exposed to light harden and develop. All covered areas stay liquid.

4. Stencil Creation

a. When the exposed screen is rinsed, the liquid parts rise off. This only leaves behind the stencil of the design.

5. Printing Prep

a. Screens are placed on the printing press, the screen printing ink is loaded, and textiles are laid on the printing board.

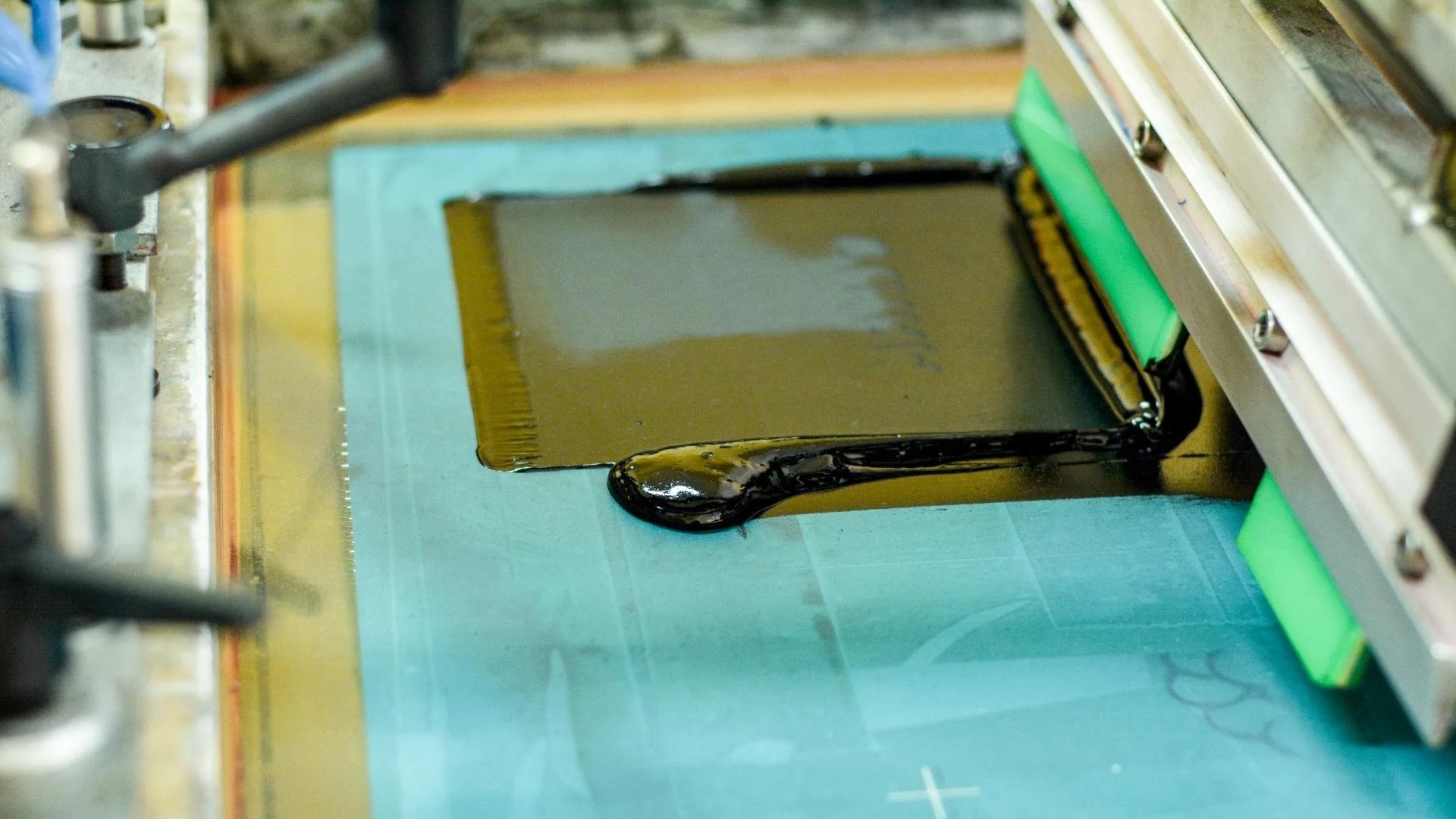

6. Inking

a. Ink is poured onto the top of the screen, above the open stencil designs.

7. Squeegeeing

a. Ink is pulled across the screen with a squeegee. Whether the squeegee is operated by a human or machine, it applies the ink directly to the substrate. If there are multiple colors and screens per substrate, the item will then move to the next screen and the ink & squeegee processes will run again.

8. Drying

a. Once all colors are applied to the item, it’s then dried. Drying the shirt, hoodies, or other items will create a smooth finish and ensure the designs last.

How to Screen Print Multiple Colors

A different screen printing technique can result in a different final product. Not all screen printing presses allow for multiple colors or they have a color limit.

History of Screen Printing

Screen printing originated in ancient China (960-1279 AD). The Japanese found new ways to apply the screen printing practice until it was adopted by Western Europeans for fabric and paper printing in the 1700s. Finally, in the 20th century, screen printing became a commonly used method for printing onto a variety of textiles. It was used by many notorious 20th century artists to print copies of their work. Finally, the screen printing process has developed into how we know it today. With over 12,471 custom screen printing businesses in the US in 2022, according to IBIS World, screen printing is alive and well.

Showoff Your Designs with Casa del Mar

Whether you’re looking to sell your fine art or print customized logo apparel, screen printing can build revenue and awareness. At Casa del Mar, we’re able to bring your vision to life. Our printing capabilities range from screen printing tee shirts to building custom new hire kits for employees. Contact us to get in touch with a custom apparel sales rep today.

Looking to expand your print, promo, or fulfillment capabilities? Check out BR Printers today to learn about our family of companies.

Sources:

https://www.ynvisible.com/news-inspiration/what-is-screen-printing

https://www.screenprinting.com/blogs/news/what-is-screen-printing

https://inkwellnation.com/tshirt-printing/everything-you-need-to-know-about-screen-printing/

https://en.wikipedia.org/wiki/Screen_printing

https://www.customplanet.co.uk/what-is-screen-printing-a-step-by-step-guide

https://www.screenprinting.com/blogs/news/screen-making-101-make-a-screen-screen-printing